Reel Hope for Ocean Conservation

Creating sustainable, cell-cultured fish fillets using cardiac tissue engineering techniques

Because he grew up between Seattle and Santa Cruz, Harvard Griffin GSAS alum John Ahrens has always lived in and around the ocean, whether surfing, kayaking, or just swimming. So, it’s fitting that last year he co-founded a company—Reel Foods—that gives back, in a unique way, to the environment he loves.

“I wanted to combine this research that I love with how I spent my time outside of the lab,” Ahrens said. “So, I thought I could apply it to ocean conservation—and that's where the idea of cultivated seafood arose.”

Building on Ahrens’s research on cultivating cardiac tissue from stem cells, Reel Foods is in the process of developing cultivated fish fillets that Ahrens hopes will be indistinguishable from the flaky fish everyone knows and enjoys. If he and his partners are successful, Ahrens’s innovation could help meet the growing global demand for seafood without further depleting the world’s oceans.

Head and Heart

Ahrens came up with the idea for Reel Foods while completing his PhD in Harvard’s Lewis Lab, where he was part of a team integrating advances from stem cell biology with 3D bioprinting to create vascularized tissues like those in human kidneys, brains, and hearts. His dissertation focused on printing cardiac tissue that could ultimately be used for repair after a heart attack, which happens when there is a blockage in one of the organ’s arteries. That blockage causes the tissue around the artery to die, after which it cannot be rejuvenated.

The main challenge of trying to recreate heart tissue is not only structural, but functional: the primary goal is to create a piece of tissue with enough contractile force to pump blood the way a human heart does.

The “raw material” of the 3D bioprinting that Ahrens did was pluripotent stem cells, which can be found in an ordinary sample of a person’s skin or blood. These cells are called pluripotent because they can end up being any type of tissue in the human body, depending on how the researcher tweaks them.

For his thesis, Ahrens used the stem cells to create cardiomyocytes, the minimum cellular units of cardiac tissue. The cells are put into what’s called a micro pillar array—which is basically a sheet of a thousand tiny wells—where they form rectangular tissue across two posts in each well. Ahrens’s thesis advisor, Jennifer Lewis, Hansjörg Wyss Professor of Biologically Inspired Engineering at the Harvard John A. Paulson School of Engineering and Applied Sciences, calls these rectangular shapes “cardiac bricks.”

“Think about it like bricks used to build a house,” Lewis said. “Each of the bricks you use in a house is anisotropic—which means it’s laid down in a single direction. What we do is take these little cardiac bricks off of their posts and put them into an ink.”

The ink contains an aqueous solution that includes nutrients the cells need to stay alive during the printing process. After the bricks are deposited into the ink, it is put into a syringe and pushed out to form a pattern of tissue.

If we want to meet the demand, we need every single strategy: from plant-based all the way through farmed fish to true cultivated fish.

–John Ahrens

“That’s the work John did for his thesis,” Lewis said, “making these bricks, tuning their properties, assembling the inks, showing that they can be printed and orientated, and then showing that, because of that, they have much better cardiac output—they have higher contractility than a non-oriented sheet.”

A second and equally important goal is replicating the vasculature within cardiac tissue that supplies it with the oxygen and nutrients it needs to survive. To replicate that vascularization, researchers like Ahrens print with “sacrificial ink”—basically a material that can be printed in cylindrical form, just like human blood vessels, and can be embedded inside a piece of cardiac tissue. After the cylinders are printed, a change in temperature causes the ink to melt, leaving tiny hollow channels that mimic blood vessels.

“My lab pioneered a technique called SWIFT, or Sacrificial Writing in Functional Tissue,” Lewis said. “We can write it deep within a very dense cellular matrix of tissue, like cardiac tissue, so it was a pretty big advance. John had a contribution to that work as well, but it was led by two other postdocs in my lab, Mark-Skylar Scott and Sébastien Uzel.”

It was during the vascularization process that Ahrens had his “Aha!” moment that made him think cultivated fish fillets could be a reality. The trio had just finished printing two tissues, one with vascularization and a control tissue without it.

“When we were first cutting these tissues, the one that was vascularized was all viable and alive,” Ahrens said. “But the other one was just this really thick tissue that was only alive on the edge—inside, it was all dead cells.”

This was about the time that cultivated meat was starting to gain awareness through the marketing efforts of several startup companies, like Meatable and Upside Foods, that produce cultivated meat and chicken.

“We were all just staring at each other,” Ahrens said. “If we ever wanted to make a true fish replacement product, this is what you would need, because the difference between the two tissues was just night and day.”

Meeting the Global Demand for Seafood

Global seafood consumption is projected to double by 2050, with demand growing steadily in Asia and mounting throughout Africa. But with an ocean supply that is already limited—wild catch has plateaued for 30 years—there's not much more human beings can extract from our oceans.

“If we want to meet the demand,” Ahrens said, “we need every single strategy: from plant-based all the way through farmed fish to true cultivated fish.”

Ahrens started Reel Foods shortly after finishing his PhD work at Harvard Griffin GSAS in September 2022. Unlike with cardiac tissue, the company doesn’t have to worry so much about functionality. When it comes to seafood, they are focused on texture. But although the fish fillets of Reel Foods won’t need to replicate the contractility of heart tissue, they will need to replicate the vascularization to replicate the structure and texture of a flaky whitefish and to keep the tissue viable while it grows into its final form as a whole-cut fillet.

Reel Foods will create their fish fillets using basically the same 3D bioprinting process Ahrens used in his doctoral research. He expects the company to be in the research and development (R&D) phase for the next few years because of the complexity of the endeavor.

“We've only really been going for about four months now,” Ahrens said, “so we're very early in R&D, working to translate these cardiac tissue engineering methods into a fish-muscle context.”

John's cardiac tissue engineering expertise, Rob's 3D printing background, and Bev's commercial experience give them an unfair advantage to bring cellular agriculture to the masses.

–Zal Bilimoria

A Capital Idea

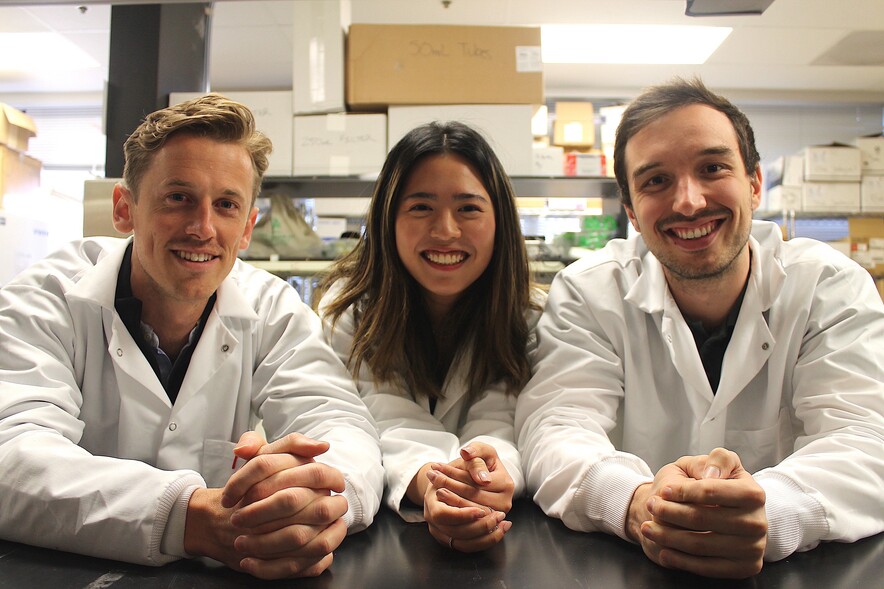

Though Reel Foods is still in its early stages, Ahrens is excited about developing its first product with his two co-founders: Robert Weeks, PhD ’23, his former Harvard Griffin GSAS lab mate; and Beverly See, who completed her MBA at Stanford University in 2021.

Weeks’s doctorate was in mechanical engineering, where he focused on developing new 3D printing methods to fabricate various (non-living) materials. See has startup experience as a former investor at General Atlantic and Apollo Global Management and helped to launch NotCo US, a growing plant-based food company.

The combination of the technique and the team at Reel Foods is why Zal Bilimoria of Refactor Capital was one of Reel Foods’s lead investors. Refactor Capital is a seed-stage venture capital firm based in California that backs projects that seek to solve fundamental human problems, primarily in climate and biotech.

“John's cardiac tissue engineering expertise, Rob's 3D printing background, and Bev's commercial experience give them an unfair advantage to bring cellular agriculture to the masses,” Bilimoria said.

Bilimoria added that proving to investors that cellular agriculture isn't a mere science project but a fundable, scalable, and real solution in a massive market will require rapid and continuous progress.

“Nothing will beat having tasting samples ready of various sushi-style cuts of seafood ahead of raising a larger seed round in the next year or two,” Bilimoria said.

To that end, Reel Foods just moved into its new lab and office space in the TomKat Center for Sustainability at Stanford University so they can grow their staff of bioengineers and materials scientists. There, the company will focus on the twin goals of proving out their manufacturing process and scaling it up for commercial production.

“I’m grateful to be able to pursue stuff like this with some of the smartest people I’ve ever met,” Ahrens said. “And it's an incredible opportunity to take it to the next step.”

Photos courtesy of John Ahrens; Banner courtesy of Shutterstock.

Get the Latest Updates

Join Our Newsletter

Subscribe to Colloquy Podcast

Simplecast